Well-Known Member

OUT OF CHARACTER INFORMATION

Intent: To sub a tough, resilient new super-material for use in future submissions.

Image Credit(s): [X]

Canon Link(s):

Primary Source(s):

- Popular Mechanics Article, 4 FEB 2015

PRODUCTION INFORMATION

Product Name: Segroth Shocksteel

Manufacturer: Segroth Materials Corporation

Affiliation: Closed-Market

Homeworld: N/A

Model: N/A

Modularity: No

Production: Mass-Produced

Material(s): Alusteel, copper filament, micro-carbon, absorbital, nickel

PHYSICAL SPECIFICATIONS

Classification: Metal

Weight: Light

Resistances –

Blasters - High

Kinetic - Low

Lightsabers - Low

Other (EMP/Ion) - Very High

Other (Sonic) - Low

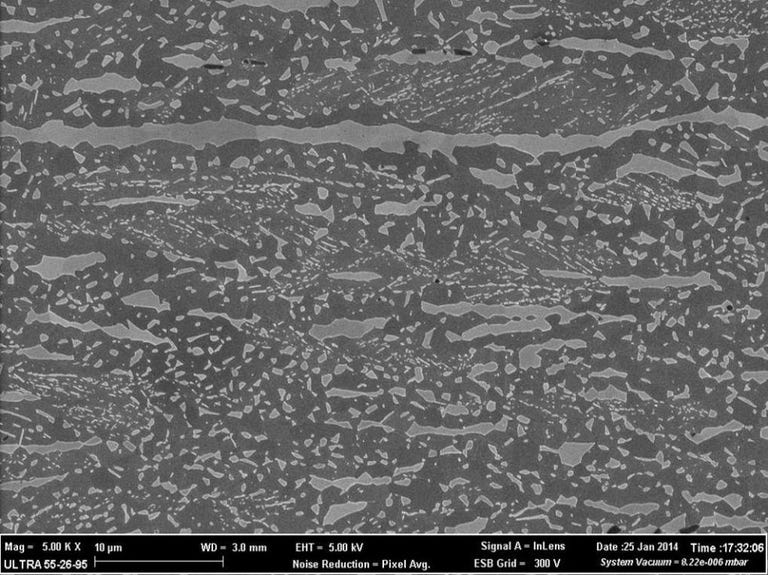

Color: Dark grey/light grey blotchy pattern with light coppery micro-hexagonal pattern throughout.

SPECIAL FEATURES

- Micro-carbon powdercoating is applied to micron-ized copper conduction wiring, which is added to the alloy, making it incredibly resistance to EMP/Ion threats.

- Aluminum-steel alloy is as strong as titanium, but significantly lighter weight, more flexible, and easier to produce.

- Increased material strength and flexibility over titanium allows for myriad uses in manufacturing to produce lighter, stronger products with exceptional resistance to EMP/Ion threats; ideals for starships, droids, all electronics products.

- Stronger than titanium and significantly more flexible and easy to work with.

- Lightweight and durable material is highly resistant to EMP/Ion threats as well as blasters and similar plasma energy weapons.

- Easier to produce than durasteel.

- Offers no significant protection against lightsabers or kinetic damage.

- Offers only marginal protection against sonic weapons, average with normal alusteel, durasteel, or titanium.

- A crushing attack will damage the copper wiring rendering it useless.

Shocksteel© is a patented product created by Segroth Materials which uses cutting-edge metallurgical science to produce one of the strongest, most versatile, and resilient alloys on the market today. Our scientists discovered that while most alusteel alloys are brittle, when the B2 crystalline structures within them grew too close together, giving the material incredible strength but causing it to be brittle. The solution was simple: An alternating heat-treating and rolling process which allows us to control when and where B2 crystals are formed. By adding a small amount of nickel to the alloy, even greater control over the process was gained. This solved the problem of brittleness and created a flexible, very lightweight material with a strength-to-weight ratio that matches even the finest titanium alloys. However, this brought a second issue to play: How to protect the material from oxidation and contamination to allow it to be put into practical use. After carefully studying a variety of potential replacements for the usual silicate protection layer used in weaker, more common metals, it was found that absorbital contained the exact necessary chemical components to offer high-grade protection and maintain material purity. When these discoveries were paired with emerging anti-EMP/Ion technologies, a miracle material was born.

By adding a tiny hexagonal pattern of micron-ized copper conduction wire filament throughout the Shocksteel, we learned that these filaments would absorb EMP/Ion energy, carrying it across the total surface of the material away from the point of contact, thereby allowing it to be dissipated and return to the air, thus rendering Shocksteel to be one of the galaxy’s most resilient metal alloys being produced today. With added benefit of high resistance to blasters and similar plasma energy weapons because of the addition of absorbital, Shocksteel is pound-for-pound a top choice for shipwrights, mechanics, electronics producers, and others in need of a lightweight, versatile, flexible, and resilient material that will hold up against wear, tear, and decay. Available only from…

SEGROTH MATERIALS: MAKING A STRONGER LIFE!

BUY IT HERE: [X]